1 / 1

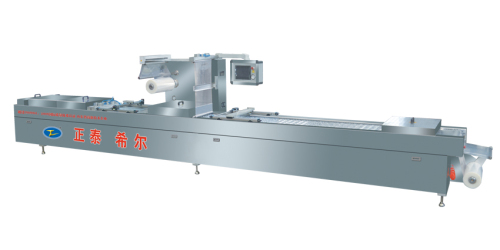

Xier Continuous Stretch Vacuum Packaging Machine

| Model No. : | DZR520 |

|---|---|

| Brand Name : | Vapack |

| Vacuum Degree : | ≤200pa |

Weifang, Shandong, China

- Pengilang

- Syarikat perdagangan

- Perkhidmatan OEM

- Pensijilan platform

- Video

Penerangan Produk

2 . The high-performance, low failure rate in Taiwan eternal PLC control system. Enable higher precision, lower failure rate, PLC lifetime warranty.

3 . The heating system used in Taiwan eternal temperature control module, man-machine interface display and operation, the display, operation and adjustment more simple and humane.

4 . Taiwan timeless precision, the inertia servo motor drive system, borrowed CNC machining center circular interpolation technology, the choice of motion control module can be adjusted to the speed of the servo motor and ensure that running accuracy of plus or minus 0.2 mm, guarantee speed high-precision operation.

5 . The machine is equipped with automatic safety protection devices, mainly related to the safety of the operator of the site is equipped with a protective cover.

6 . HMI plus PLC centralized control, substantially all of the operations can be done on the touch screen (installation, except in the film). Whether crosscut knife choice or coding, etc. as long as the number of rows on the touch screen to make simple adjustments.

7 . faulty touch screen and servo amplifiers can prompt the cause of the failures and parking, the machine with a plurality of automatic alarm is automatically displayed.

8 . The optical tracking system used by the US imported three-color mark sensor, can sense all colors and strong output signal, be sure to use color film, color film and can be molded with the bottom zone accurately aligned.

9 . The low-voltage electrical control system uses a well-known international brands Schneider Electric, with over-current, over-voltage and overload protection.

10 . The machine adopts frame structure, all materials used food-grade stainless steel and aluminum alloy 3042B assembled.

11 . The high quality stainless steel chain drive system and a film clip; ensure clamping force film clip, drive effectiveness and service life, warranty decade.

12 . The pneumatic part of the original Airtac solenoid valves and cylinders, and centralized modular pneumatic valve terminal system that allows operational stability and reliability. Vacuum system uses pneumatic valve islands off and pneumatic bleed, ensure more stable performance in high-frequency use, longer life.

13 . The top and bottom of the film adopt advanced inflatable roller fixing and positioning technology, more convenient, lower failure rate.

14 . The independent upgrade system adopts link auxiliary lift, ensure that the studio is not deformed at high sealing pressure does not shift. Maintenance, maintenance more convenient.

15 . The independent brakes and automatic tensioning system, to ensure the operation, the next film can not afford to film and deviation, the top of the chain to ensure high-speed operation, the base film is not due to jitter affect the work.

16 . with a powerful waste recycling system to ensure that both sides of the base film is timely and effective waste recycling.

17 . The product is equipped with individual customers and transverse slitting knives, each cross knife achieve individual control and operation. Each is equipped with a mold and a slitter knife, quickly adjust to ensure timely replacement of each mold (including cross-cutting knives, slitters and material support, etc.) to replace only a few minutes.

18 . equipped with Germany imported BUSCH202 type vacuum pump and 40 green environmental protection type vacuum pump system. Vacuum chamber 202 individually controlled vacuum pump exhaust rate up to 202 cubic meters per hour, can reach ultimate vacuum 0.1mbar, strong power of 5.5KW. Forming chamber type vacuum pump 40 alone controls to ensure high pumping speed, high vacuum and high efficiency.

19 . using integrated film brake mechanism can be quickly and accurately brake film, color film and the base film so accurately aligned.

20 . Optional three sets of molds according to customer requirements.

Worth you rely on vacuum packaging machine expert, provide global food security, the main products include: automatic vacuum packaging machine, stretch film vacuum packaging machines, automatic vacuum thermoforming packaging machine, factory vacuum packaging machines, vacuum packaging lines manual vacuum packaging machines, automatic stretch film wrapping machine, a continuous stretch packaging machines, all kinds of custom-made vacuum packaging machine.

Weifang, Shandong, China

- Pengilang

- Syarikat perdagangan

- Perkhidmatan OEM

- Pensijilan platform

- Video

Hantarkan pertanyaan anda kepada pembekal ini