Video

1 / 1

Mesin penampalan tetingkap automatik dengan berkerut dan memotong

$29000.00

≥1 Set/Sets

| Model No. : | ZXTC-650/850 |

|---|---|

| Brand Name : | Innovo |

| Applicable industry : | Manufacturing Plant,Advertising Company,Printing Shops |

Chuzhou, Anhui, China

- Pengilang

- Perkhidmatan OEM

- Pembekal Emas

- Pensijilan platform

Penerangan Produk

ZXTC-650/850 Mesin Patching Window Automatik dengan Pemotongan dan Berkelanjutan

Struktur Mesin: Bahagian pemakanan kertas, bahagian kedudukan, bahagian pelekat, bahagian melekat filem, bahagian penghantaran kertas.

Kegunaan: Sesuai untuk penggambaran tingkap automatik karton tingkap seperti kotak tisu, kotak kosmetik, kotak hadiah, kotak pakaian, kotak mainan, dan lain-lain. Kertas bergelombang juga sesuai, dan karton berbentuk khas juga mudah dioperasikan.

Nota: Bahagian yang dibeli yang digunakan untuk mesin dalam kontrak ini akan digantikan dengan produk tahap yang sama yang tidak lebih rendah daripada kualiti jenama sedia ada apabila peralatan dinaik taraf atau dikemas kini. Penjual akan berhak tanpa notis lanjut.

Parameter teknikal :

|

Model |

ZXTC-650 |

ZXTC-850 |

|

Applicable paper range |

160*160mm---580*650mm |

160*160mm---580*850mm |

|

Applicable paper grams |

200g---3000g |

200g---3000g |

|

Film size range |

50*20mm----340*320mm |

50*20mm----340*400mm |

|

Film thickness range |

0.038--0.25mm |

0.038--0.25mm |

|

Speed of work |

10000--13000pcs/h |

10000--13000pcs/h |

|

Indentation speed |

0-5000pcs/h |

0-5000pcs/h |

|

power |

6kw |

6kw |

|

Machine size (L*w*h) |

4600*1300*1600mm |

4600*1500*1600mm |

|

Machine weight |

1.5Ton |

2Ton |

Peralatan asas

|

Paper Feeding |

|

|

|

The intermittent belt conveying method adopts an independent servo control system, and the intermittent conveying distance can be adjusted according to the length of the paper; the paper-pumping belt draws paper at the bottom, eliminating the traditional clutch control method. In this way, continuous paper feeding can be realized without stopping; the left and right position of the belt can be adjusted quickly. |

|

Positioning Department |

|

|

|

The track belt self-locking linear bearing freely slides to replace the disadvantage of slow manual adjustment of traditional screw power transmission. The polymer nylon material track has low noise and wear resistance. The correction positioning pin is driven by a servo motor alone. |

|

Glue pasting |

|

|

|

The gluing roller is made from 304 Stainless steel material which is in high corrosion resistance and is easy to clean. Transverse and longitudinal gluing model roller are driven by servo motor which can realize the dual-directional regulation directly without stopping. The gluing part is equipped with the automatic lifting function. It avoids the glue touching the belt which reduces the trouble of frequently machine stop for cleaning because of the lack |

|

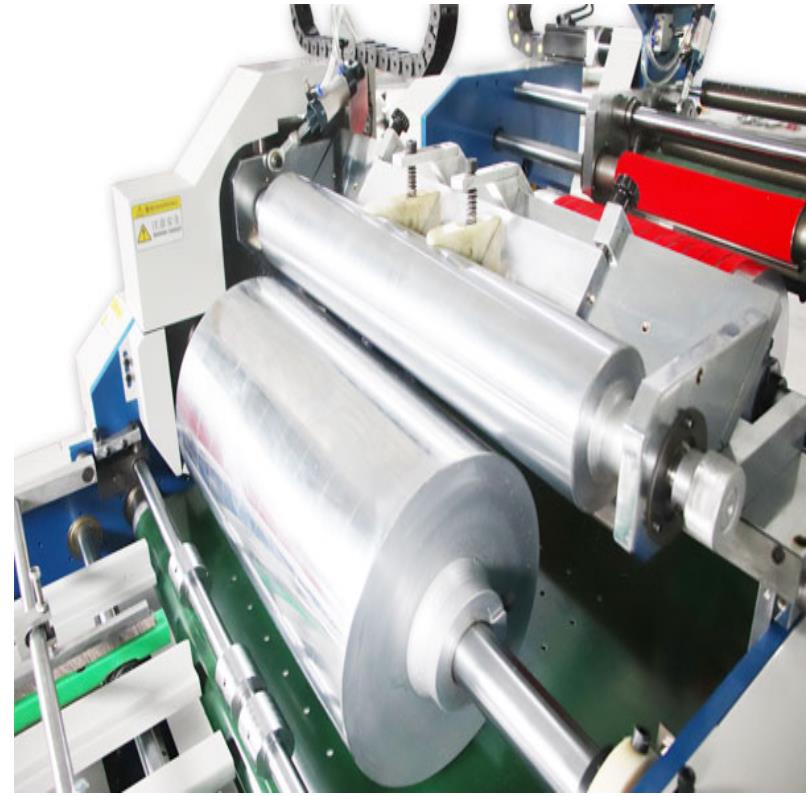

Filming |

|

|

|

1. Using an independent servo control system, users can adjust the length of the film according to the product size without stopping the machine. 2. With two film frames, two windows can be pasted at the same time to improve production efficiency 3. Adopt upper and lower hob cutting film design, suction roller to suck film, automatic and fast film sticking |

|

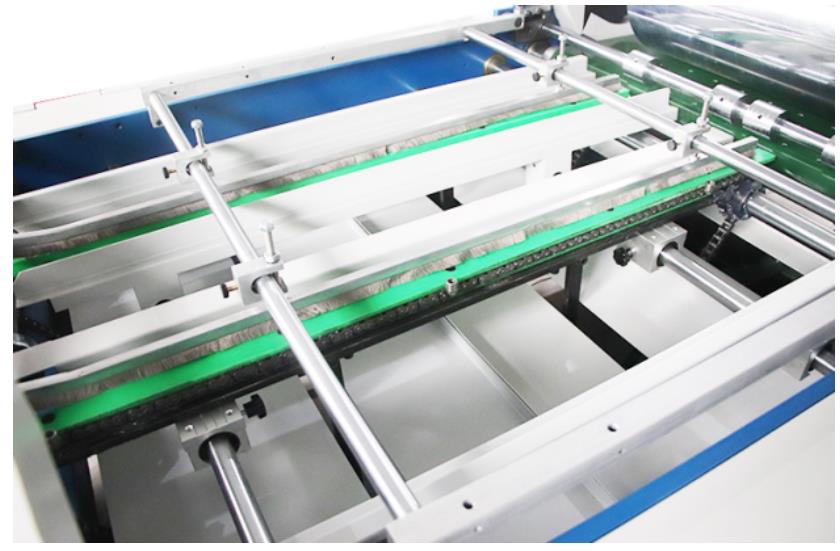

collecting paper |

|

|

|

1. The delivery table adopts stepping motor, which can be continuous, pause, and flexible use of points 2. The high-quality moderate belt conveying can avoid crushing the product, and the stacking neatly collects paper to ensure perfect quality. Improve paper delivery efficiency |

Video

Chuzhou, Anhui, China

- Pengilang

- Perkhidmatan OEM

- Pembekal Emas

- Pensijilan platform

Hantarkan pertanyaan anda kepada pembekal ini