1 / 3

65ZJW Filter Press Feeding Pumps

$5000.00

≥1 Set/Sets

| Model No. : | 65ZJW |

|---|---|

| Brand Name : | NAIPU |

| Type : | Clay Wet Sand |

Shijiazhuang, Hebei, China

- Pengilang

- Perkhidmatan OEM

- Pembekal Emas

- Pensijilan platform

- Pensijilan SGS

- Ekspo dalam talian

Penerangan Produk

65 zjw Pam Penyumpan Tekan Penapis

Pam buburan emparan mendatar julur/pam buburan berlapik getah/pam buburan R55 /pam buburan pengedap kelenjar/pam buburan pengedap emparan/pam buburan getah tahan haus/pam buburan boleh tukar ganti/Pam buburan cucian arang batu/Pasir dan graviti pam tangan pam /pam pemprosesan pengapungan galian/pam basuh arang batu/Pam Pemakanan

Pam suapan tekan penapis siri Naipu® NP-ZJW menerima desin hidraulik yang unik dan mod pemasangan

pendesak, memastikan bahawa lengkung prestasi pamnya lebih curam daripada pam biasa, lebih sesuai digunakan dalam

suapan tekan penapis berbeza-beza mengikut perubahan rintangan untuk merealisasikan kapasiti yang besar,

penyusuan tekanan rendah dan kapasiti rendah, penapis tekanan tinggi. Pam digunakan secara meluas dalam pencuci arang batu,

perlindungan alam sekitar, kilang aluminium, loji peleburan dll.

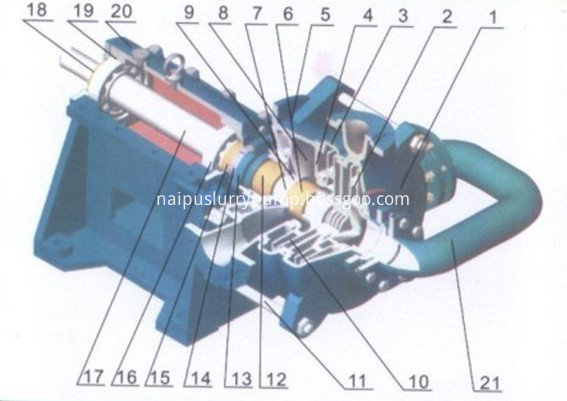

Lukisan Pembinaan

Carta struktur pam suapan

1.Volut dua fasa 2.Pendesak dua fasa

3.Volut satu fasa 4.Plat belakang

5.Bilik makan 6.Locating semak

7.Expeller 8.Expeller plat penutup

9.Badan penyahmampatan 10.Pendesak satu fasa

11. Palang pengikat 12. Lengan aci

13.Plat penutup 14.Gelang pembuka

15.Plat penahan air 16.Bearing

17.Shaft 18.Bearing spacer sleeve

19. Penutup galas 20. Bingkai

21. Paip bengkok

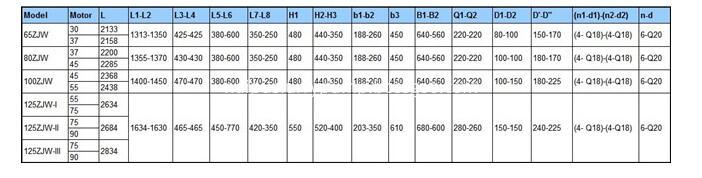

CARTA PEMILIHAN PAM NP-ZJW

PARAMETER PRESTASI PAM SUAPAN NP-ZJW

Gambaran Keseluruhan Produk:

Kemungkinan Kesalahan dan Penyelesaian.

|

Faults |

Reason |

Settlement |

|

1.Pump fails to discharge any water,The hand of pressure gauge beat violently |

1.Suction pipe don`t have enough water. 2.Suction pipe blocked or the valve is locked. |

1. Inject enough water 2.unlock the inlet valve,clear the blocks 3.Exclude the air leakage |

|

2.The pump can`t discharge water,the hand of vacuum meter beat heavily. |

1.The inlet valve is unlocked or silted up. 2.The resistance of suction pipe is too big or silted up. 3.The height of suction is too high. |

1.Unlock the valve or desilting 2.improve the design of suction pipe or desilt 3.Lower the height of the installation. |

|

3.The pump can`t discharge water,pressure gauge shows heavy pressure. |

1.The resistance of the discharge pipe is too big. 2.The impeller blocked 3.The speed is slow. |

1.Check and adjust the outlet pipe. 2.Clear the impeller 3. Improve the speed. |

|

4.The pump doesn`t rotate |

The volute is silted up by the blocks. |

Clear the blocks |

|

5.The capacity is not enough |

1.The blocks of the impeller or the inlet or outlet pipe. 2.The abrasion of the impeller is heavily. 3.The speed is low to normal 4.Pump is installed unreasonably or the leakage of the inlet pipe. 5.The transporting height is too high,the loss of the resistance of the inside pipe are too big. 6.The inlet valve not open enough or blocked 7.The packing seal leaks |

1.Clear the impeller or pipe. 2.Change the impeller

3.Adjust the speed 4.Install again or stop leaking.

5.Decrease the height of the transport or reduce the resistance. 6.Unlock the inlet valve

7.Compress the packing tightly |

|

6.The motor of the pump is overloaded |

1.The head of the pump exceeds the head of the working condition. 2.Not consider the slurry density when selecting the pump. 3.The packing press tightly |

1.Turn down the outlet valve,cut the impeller or lower the speed. 2.Select the motor again. 3.Adjust the the screw of the packing gland |

|

7.Abnormal sound in the pump, and no water out |

1.The resistance of the inlet pipe is too big. 2.The height of the suction is too high. 3.Cavitation occurred 4.there is air in the inlet 5.The temperature of the liquid is too high |

1.Clear the suction pipe and sluice valve. 2.Lower the height of the suction 3.Adjust the water valve and let the pump operate in the defined limits. 4.Block the leakage. 5.Lowering the liquid temperature. |

|

8.pump vibrates |

1.pump cavitate 2.The block of the impeller single vane 3.The no concentricity between the pump shaft and motor shaft 4.Fasteners or foundation loose |

1.Adjust the water valve ,lower the height of the installation,reduce the resistance of the inlet. 2.Clear the impeller 3.Alignment again 4.Fasten the screw,and reinforce the foundation. |

|

9.Bearing is overheat |

1.lock the cooling water 2.lubrication is not good. 3.the lubrication oil is not clear 4.the wrong direction of the thrust bearing. 5.there is something wrong with the bearing. |

1.Open the cooling water 2.Adjust the oil quantity 3.Clear the shaft,change oil 4.According to the inlet pressure,adjust the direction of the thrust bearing. 5.Change the bearing |

|

10.Packing short life |

The material of packing is not good |

Change the packing |

|

11.pump leak oil |

1.High oil level 2.The rubber parts invalid 3.Assembly problem |

1.Lower the oil level 2.Change rubber spares 3.Adjust the assembly

|

|

12 Pump head leaking |

1.The rubber parts not press well |

Assembly again or press tightly |

Soalan Lazim:

S1. Adakah anda kilang pengilang?

Ya, kami adalah kilang pembuatan langsung, dan mempunyai pengalaman lebih daripada 10 tahun dalam bidang ini.

S2. Adakah anda mempunyai produk stok untuk dijual?

Ada yang kami ada dalam stok, tetapi yang lain tidak. Oleh kerana kami sentiasa menghasilkan produk ini mengikut keperluan pelanggan.

S3. Apakah kelebihan yang anda ada?

A: Kami adalah pengilang langsung dan harganya kompetitif.

B: Jurutera kami sangat berpengalaman dalam bidang ini, dan kami boleh melakukan perkhidmatan OEM kepada anda.

C: Kami adalah kilang, dan kami boleh mengatur jadual pengeluaran, supaya penghantaran tepat pada masanya.

Butiran kenalan:

Shijiazhuang Naipu Pump Co.,Ltd.

Tambah:No.368 Xinshi North Road,Shijiazhuang Hi-Tech Industri Zon Pembangunan, Hebei,China,050091.

Tel:0086-311-897162903

Faks:0086-311-87162902

Orang Yang Dihubungi: Karen Tan

Skype: karen_naipump

Shijiazhuang, Hebei, China

- Pengilang

- Perkhidmatan OEM

- Pembekal Emas

- Pensijilan platform

- Pensijilan SGS

- Ekspo dalam talian

Hantarkan pertanyaan anda kepada pembekal ini