1 / 2

Flowmeter Rotor Spiral Produk Baru

Options:

- Cast iron

- Cast steel

- Stainless steel

- 0.5

- 0.2

| Brand Name : | JiBO |

|---|---|

| Warranty : | 1 Year |

Penerangan Produk

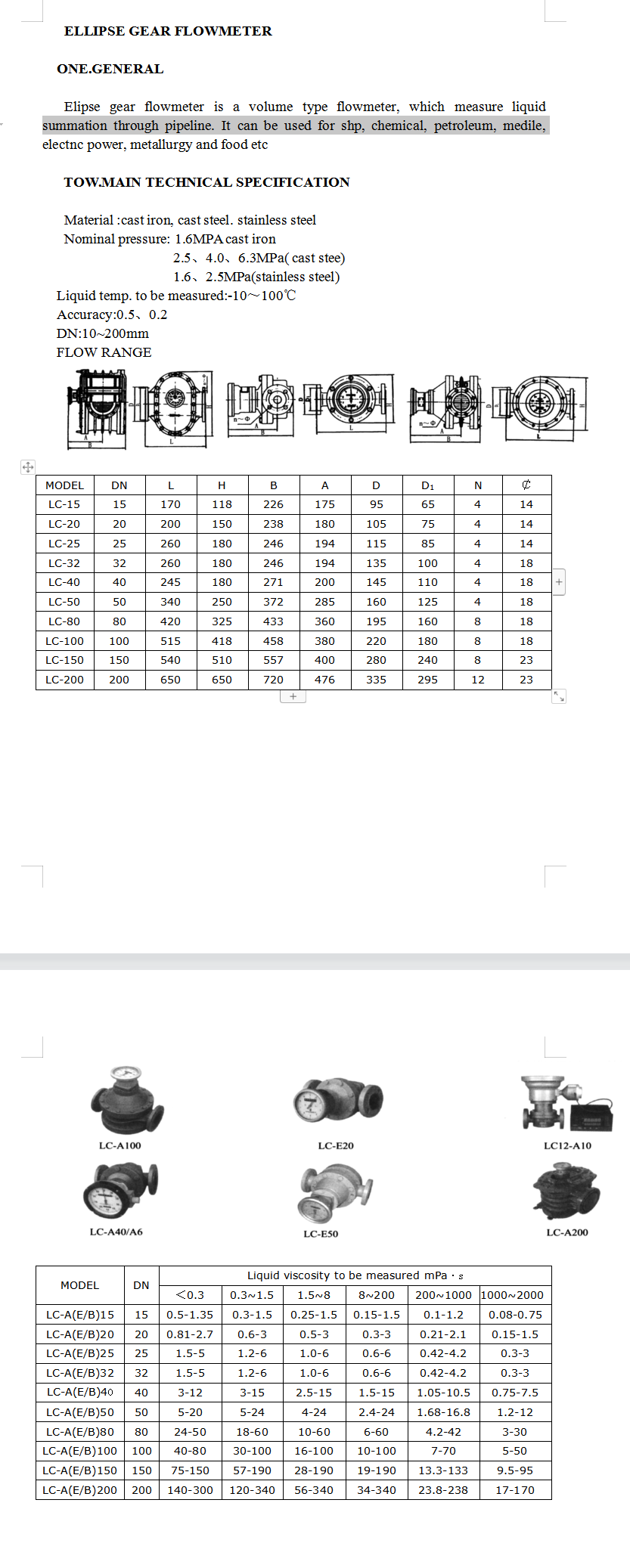

The Marine Helical Rotor Flowmeter is a high precision meter for continuous or intermittent measurement of flow in pipelines. The Lzx Type Marine Helical Rotor Flowmeter has the characteristics of high accuracy, good reliability, light weight, long life, easy installation and use, etc., which are typical characteristics of positive displacement flowmeters. Spiral Rotor Flowmeter is mainly composed of three parts: metering chamber, sealing coupling and counter. The cumulative flow and instantaneous flow can be indicated on the spot, and together with a transmitter and a flow intelligent controller, it can realize long-distance measurement and control. Widely used in petroleum, chemical, electric power, metallurgy, transportation, food processing, medicine, national defense, commercial trade and other departments to accurately measure oil, petroleum products, chemical solutions and other fluids.

1. Commissioning

After correct installation and check, newly designed or newly installed helical rotor flowmeter system should be inspected for commissioning following the procedures as follows.

1) Close forward and after valves (switch valve and control valve) of the flowmeter, slowly open bypass valve (for the horizontal installation type, bypass valve is in the bypass pipeline, for the vertical installation type, bypass valve is in the main pipeline, see figure 4-21) to make the fluid flow through bypass valve to wash the remaining impurities inside the pipeline in order to make pressure balance between inlet and outlet. I f there is no bypass pipeline, use one short pipe instead of flowmeter in the pipeline to make the fluid flow, after cleaning remove the short pipe instead of flowmeter.

2) Start up flowmeter, for accumulated flowmeter with remote transmission, first connect signal line and power line and energize for preheating, then slowly open forward switch valve of flowmeter and after control valve, finally slowly close bypass valve. U se control valve in the outlet to control flow to make flowmeter work in normal flow.

I f temperature of the fluid to be measured is very high with big difference comparing to ambient temperature, then flowmeter system should be preheated before running to make flowmeter and pipeline system slowly warm up in order to ensure normal running of flowmeter.

3) Observe and record parameters change of each item, such as temperature and pressure, the system should be no great vibration, noise and leakage etc. During period of steady running, the commissioning will be finished.

2. Normal operation

After helical rotor flowmeter is put into normal operation through normal commissioning, operator should do usage and maintenance as following items.

1) During operation, observe flow, temperature, pressure and viscosity of measured fluid to check if the parameters accord with usage range of flowmeter, if the d ifference is bigger, should find out reason and consider compensation.

2) S tart up and close up flowmeter according to the order of commissioning. I n general, strict operation procedures and rules should be worked out, including usage regulations, inspecting operat ion instruction and period, troubleshooting procedure, activation provision of standby flowmeter and seals of flowmeter and bypass valve etc.

3) C heck, maintain and inspect whole flowmeter system periodically, including flowmeter, valves and pipelines, matched devices as filter and LPX etc., measuring instruments thermometer, pressure gauges and densimeter etc., protecting devices relief valve, metering valve and annunciator etc., and flow auxiliary devices as flow indicating instrument, record fitting, compensating fitting etc..

W hen the temperature of measured fluid is higher than 80 ℃ , max. flow of flowmeter is 90% of original max. flow, and min. flow is 120% of original min. flow.

|

Name

|

Elipse gear flowmeter

|

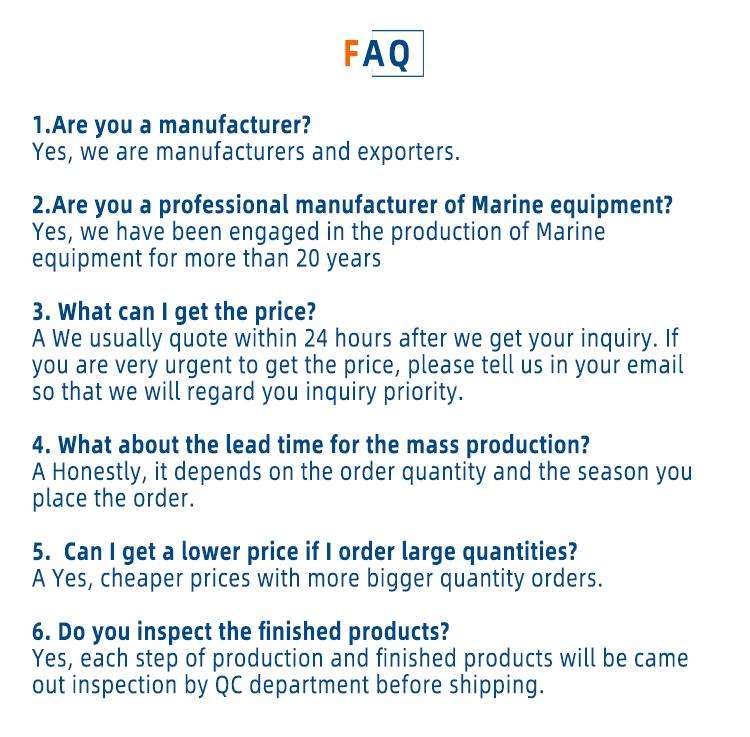

Hantarkan pertanyaan anda kepada pembekal ini