Video

1 / 6

Jubin Langkah Membentuk Mesin Mesin Lembaran Dinding

$23500.00

≥1 Set/Sets

Model:

- XF 25-10

Power (Watts):

- 5.5+5.5Kw

| Model No. : | XF 25-10 |

|---|---|

| Brand Name : | Xf |

| Applicable industry : | Building Material Shops |

Cangzhou, Hebei, China

- Pengilang

- Perkhidmatan OEM

- Pensijilan platform

- Pensijilan SGS

- Ekspo dalam talian

- Video

Penerangan Produk

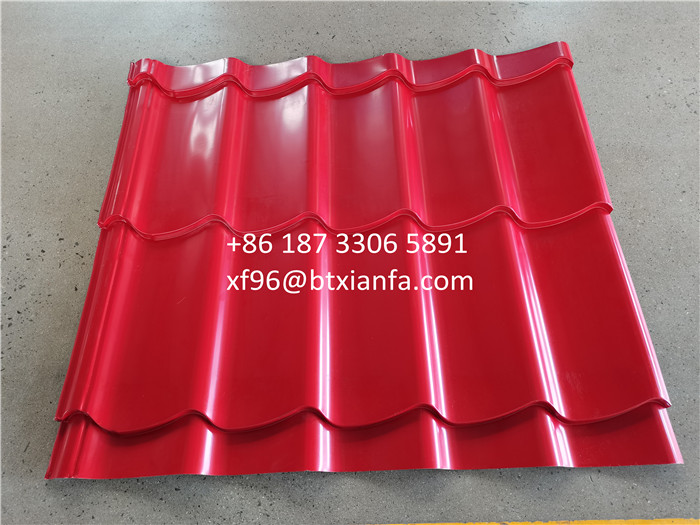

Double Layer Glazed Tile Roll Forming Machine for Turkmenistan. The upper layer is Glazed Tile Roll Forming Machine, the down layer is Wall Roll Forming Machine. The power of Double Layer Sheet Roll Forming Machine is 5.5+5.5Kw. The feeding material of coils for Roofing Sheet Machine is 1000mm, 0.3-0.8mm. If you need other Roll Forming Machine Series, such as Gutter Roll Forming Machine, Downpipe Roll Forming Machine and Ridge Cap Roll Forming Machine,pls contact us. Detailed quotation will share with you.

Double Layer Roll Forming Machine

Equipment Detailed Parameters

|

No |

|

|

|

1 |

Suitable Material |

Colored Steel plate, Galvanized Board |

|

2 |

Width of the raw material |

1000 mm |

|

3 |

Rows of rollers |

Upper level :12 Rows Down level :10 Rows |

|

4 |

Appearance size |

About 10*1.5*1.7 m |

|

5 |

Total power |

5.5+5.5 Kw |

|

6 |

Thickness of raw material |

0.3-0.8 mm |

|

7 |

Productivity |

Upper level :0-4 m/min Down level:8-15 m/min |

|

8 |

Diameter of shaft |

¢70 mm |

|

9 |

Voltage |

380 V 50 Hz 3 phase |

Components and Technical Specification

Manual Uncoiler: Usage: It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity: 5 Tons Inner diameter: 470-530 mm

Main Roll Forming Machine: Material of rollers:45# steel , roller surfaces polishing, hard plating , The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Hydraulic oil: 40#

hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one.

The system is easy to operate and use.

Frequency converter:Delta

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12,quenching treatment

1.We have professional technicians for loading

Guaranteed the goods load into container without any damage.

2. Transportation : Machines need one 40 feet container to hold

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

perkhidmatan kami

1. Warranty :One year,and we will provide technical support for whole life of the equipment.

2. Delivery time: Within 30 days after deposit receipt your payment

3. Guarantee period: 18months free service/ pay service all the machine life

4. Installation and training If buyers visit our factory and check the machine

we will teach you how to install and use the machine and also train your workers/technician face to face.

Without visiting,we will send you user manual and video to teach you to install and operate.

If buyer needs our technician to go to your local factory,please arrange board and lodging and other necessary things.

For detail quotations, Please Contact Below

Video

Cangzhou, Hebei, China

- Pengilang

- Perkhidmatan OEM

- Pensijilan platform

- Pensijilan SGS

- Ekspo dalam talian

- Video

Hantarkan pertanyaan anda kepada pembekal ini